- Shine Reflects our quality

- +91 7588055554 / +91 9921153740

Our Services

We Provide Greate Services for our Clients in All Projects

We provide innovative Product Solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.

Why Choose Us

We have facility to produce advance work various industrial applications based on specially developed technol-ogy. We are also ready to developement by according to users changing needs. Infrastructure related installation projects.

General repair & industrial and machinery. Our team up-to-date, sustainable custom manufacturing solutions.

- Great Technology

- Skilled Engineers

- Delivery Ontime

- Best Branding

Our Projects

- VIEW ALL

- Roller Cages Spur

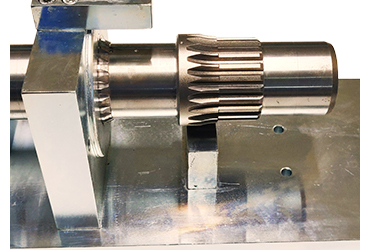

- Roller Cages Shaft

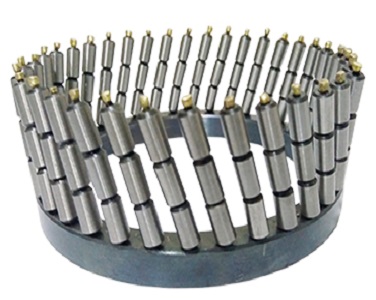

- Roller Cages

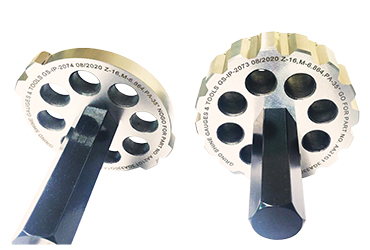

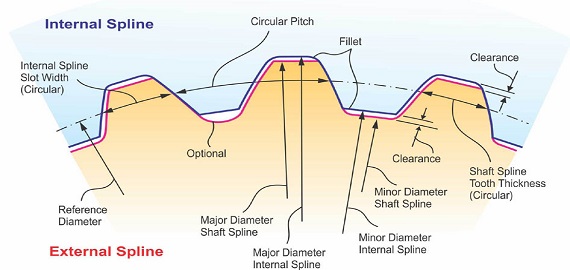

- Special Gauges

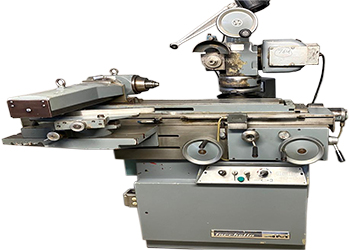

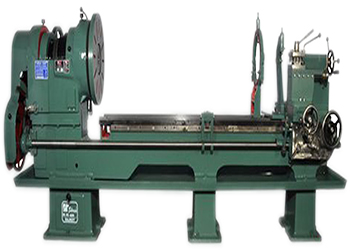

Our Machines

This whats makes shine into quality